High-Quality Services

Whether you are involved in manufacturing or managing industrial assets, verifying the integrity of materials is a top priority. The quality of welding and other production processes can literally make or break your success.

Our effective non-destructive testing (NDT) services help you detect defects in raw materials, products, facilities and equipment. This provides asset management data that allows you to prevent damage and associated costs resulting from material failure. From the procurement and production phase to the end of the asset lifecycle, we help you monitor the integrity of your equipment.

Ultimately, our NDT services help you achieve operational efficiency and ensure compliance with applicable standards.

Contact Us

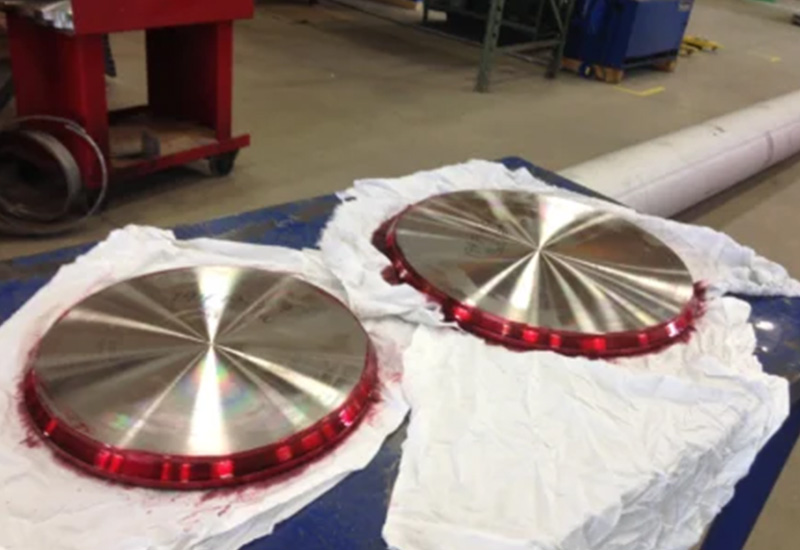

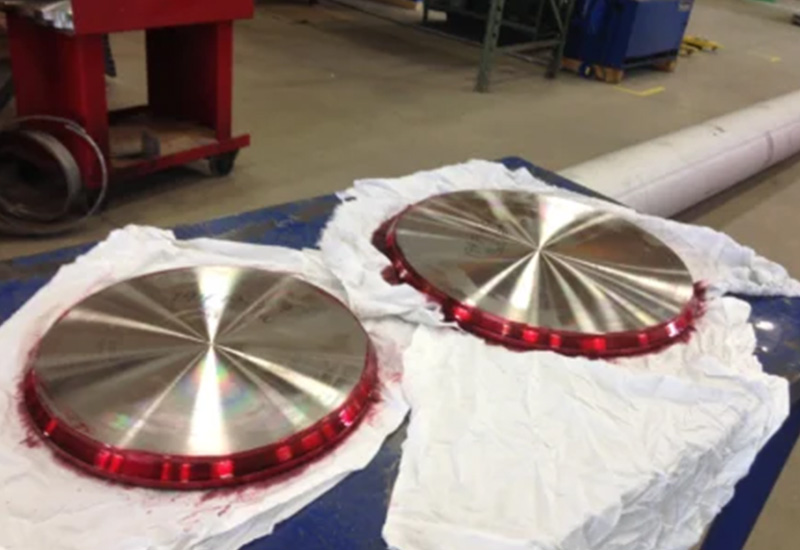

Magnetic Particle Inspection (MT)

Finding surface defects in ferromagnetic metals.

Magnetic Particle Inspection (MPI) or Magnetoscopy is an NDT (Non-Destructive Testing) method used to check the surface integrity of ferromagnetic materials such as carbon and chrome steels, martensitic stainless steels (410, 410NiMo, CA-6NM, 440, etc.), ferritic stainless steels (405, 409, 430, 442, etc.), and cast irons. The material is magnetized using a portable electromagnet or a horizontal MPI bench.

Surface or near-surface defects cause a 'leak' in the magnetic field flux. When a liquid containing tiny magnetic particles or fine iron powder is applied, these particles accumulate around these discontinuities, making them visible to the naked eye. If necessary, a white contrast agent is applied to the material before testing. For high sensitivity, a fluorescent liquid and ultraviolet light may be used.

Ultrasonic Testing (UT)

Using sound waves to look inside the material

Ultrasonic testing (UT) is a volumetric Non-Destructive Testing (NDT) method. Unlike surface inspection methods, UT enables the detection of internal defects within a material. High-frequency sound waves are transmitted into the material using an ultrasonic transducer. These sound waves reflect off material defects and are displayed as a graph. Ultrasonic testing provides real-time insights into the depth, size, nature, and orientation of detected indications with excellent accuracy.

The thickness of a material, such as the wall thickness of pipes, can also be measured to assess thickness loss caused by corrosion and erosion. CNDT Services has extensive experience in applying UT inspections across all industrial sectors.

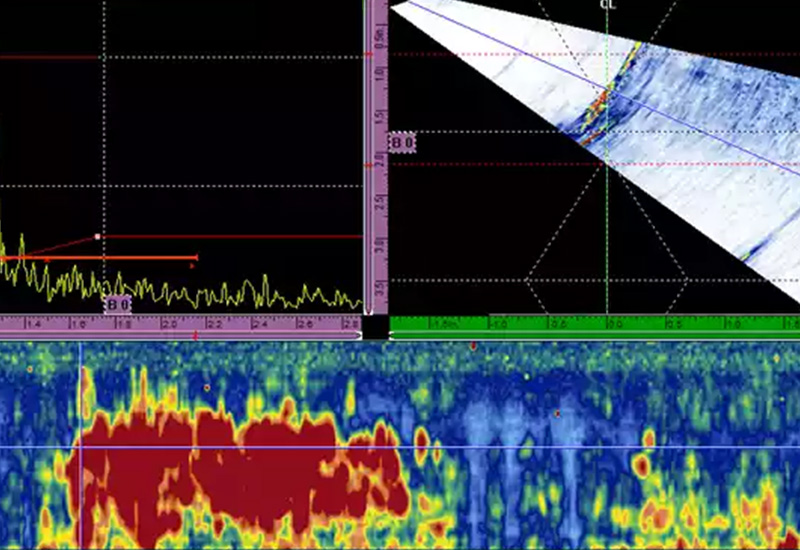

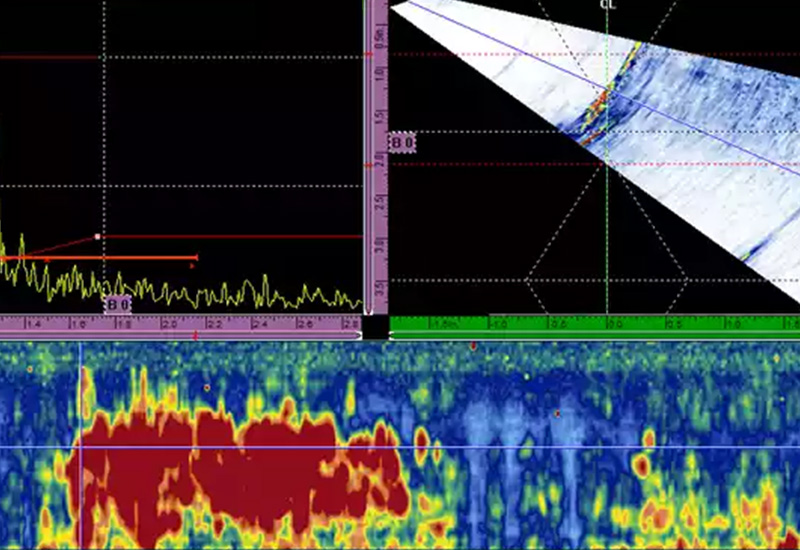

Phased Array Ultrasonic Testing (PAUT)

Phased Array Ultrasonic Testing (PAUT) is an advanced application of ultrasonic testing technology. It is used for weld inspections, crack and defect detection, thickness measurements, and corrosion inspections. Due to its detailed visualization of the size, shape, depth, and orientation of defects, Phased Array can often be used as an alternative to radiographic testing. Since it does not involve ionizing radiation, there is no need to establish a safety zone, which typically requires a production shutdown.

In conventional UT testing, a single transducer sends ultrasonic waves into the material. Phased Array probes contain multiple transducers. By introducing a delay between the pulses emitted by each transducer, the beam angle, focal point, and wavefront focus can be adjusted. This makes Phased Array Ultrasonic Testing a highly versatile method suitable for complex geometries.

Dye Penetrant Testing (PT)

Dye penetrant testing (PT) is used to detect surface-breaking defects. PT inspection is suitable for a wide range of materials, but it is mainly used on non-porous materials, especially non-ferromagnetic materials.

Austenitic stainless steels (304, 308, 309, 316, 321, 347, etc.), non-ferrous metals (aluminum, titanium, magnesium, copper, bronze, brass, etc.), ceramics, and plastics.

This method uses the principle of capillarity. A low-viscosity liquid dye is applied to the part to be inspected. Due to its low viscosity, it is drawn into surface discontinuities. After allowing sufficient penetration time, the excess penetrant liquid is rinsed off. After drying, a chalk-like developer is applied. The developer highlights indications, making them visible and interpretable by the inspector.

Two types of penetrants are used: visible Type I and fluorescent Type II.

Visual Inspection (VT)

Keeping a close eye on quality

Visual Inspection (VT) is arguably the oldest and most widely used NDT method. It plays an essential role in non-destructive testing. For thousands of years, artisans have used their eyes to determine the quality of the products they create. Essentially, this is still the case with visual inspection. This method involves the visual observation of a test object's surface to assess the presence of surface discontinuities such as corrosion, misalignment, physical damage, and cracks.

Visual tests can be performed by directly looking at the specimen or using optical instruments such as magnifying glasses, mirrors, endoscopes, and computer-assisted visualization systems. VT applies to inspections of cast parts, forged parts, machined components, and welds.

Visual inspection also considers the importance of monitoring and adhering to procedures during welding operations. Our inspectors have expertise in these areas and hold certifications in accordance with CSA W178.2 standards.

Structural Inspection

Structural inspection of lifting equipment such as cranes, lifts, platforms, forklifts, hoists, and concrete pumps should be done periodically to detect anomalies in the structure. The goal of inspecting the structure of lifting equipment is:

- Ensure worker safety

- Avoid productivity losses due to equipment breakdowns

- Increase equipment longevity

The failure of a structure during use can cause significant material and physical damage, potentially leading to death.

Welding Monitoring

Welding monitoring is a critical step in the manufacturing process, particularly in the construction, fabrication, equipment production, and metallurgical industries.

- Ensure that the quality of welded fabrications meets standards and requirements.

- Verify the entire manufacturing range.

- Inspect at different stages of manufacturing: before welding, during welding, and after welding.

- This process involves careful visual examination and quality control of welds by qualified inspectors.

Training

Training in non-destructive testing (NDT) and metallurgy is crucial for ensuring the quality, safety, and reliability of materials and structures in various industrial sectors such as aerospace, automotive, oil and gas, shipbuilding, and many more. This training equips professionals with the necessary skills and knowledge to conduct precise inspections, interpret results, and make informed decisions.

Remote Region Inspection

Remote industrial sites, offshore/onshore oil and gas facilities, remote mines, or remote construction sites often require specific inspection techniques due to their limited access, extreme environmental conditions, and logistical constraints.

Our qualified inspectors will be there to assist you.

Research and Development

Our goal is to enhance the performance, sensitivity, precision, and efficiency of NDT techniques, while also developing new methods and technologies to meet the growing needs of various industries.

One of the primary motivations for research and development is to optimize existing techniques to detect increasingly smaller and more subtle defects, while reducing false positives and improving the reliability of results.