Magnetic Particle Inspection (MT)

Detects surface or subsurface defects on ferromagnetic materials.

Ultrasonic Testing (UT)

Uses high-frequency sound waves to detect internal defects in materials being inspected.

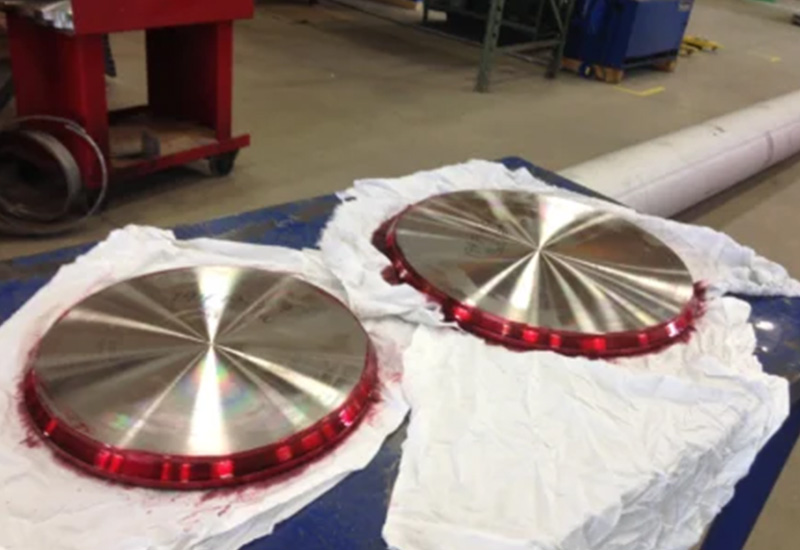

Dye Penetrant Testing (PT)

Detects surface defects using colored indicators, ensuring material integrity.

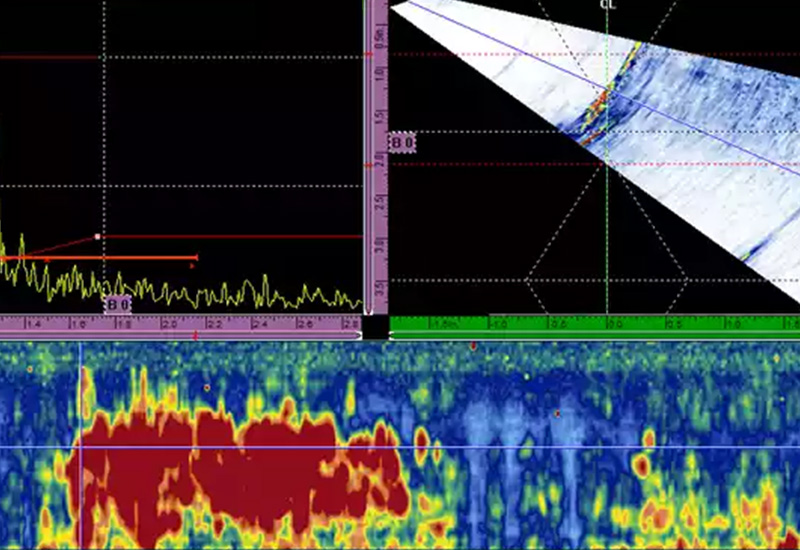

Phased Array Ultrasonic Testing (PAUT)

Uses adjustable ultrasonic beams to inspect and detect internal defects in materials.

Structural Inspection

Assesses the condition and integrity of structures by detecting potential defects and anomalies.

Visual Inspection (VT)

Visually examines components to ensure quality and compliance, before, during, and after welding.

Welding Supervision

In the metallurgical industry, ensures that the quality of welded products meets standards and requirements.

Training

Training on Various Non-Destructive Testing Techniques, Metallurgy, and Materials and Processes.

Remote Region Inspection

We offer our services everywhere, including remote regions.

Research and Development

Develop new methods and technologies to improve performance, sensitivity, precision, and efficiency in non-destructive testing techniques.

Certified and Experienced Inspectors

CNDT Services Inc. is a respected choice partner for its expertise, experience in industrial equipment inspection, and mastery of non-destructive testing methods for materials and quality control.

- Reliability and Expertise

- Quality and Precision

- Professionalism

- Safety

- Efficiency

- Innovation

Flexibility

Tailored Team for Unobstructed Inspections

We take into account the reality of each of our clients and will adapt to changes and unforeseen circumstances. This flexibility minimizes time loss and ensures inspections are conducted without disrupting other production phases, in perfect collaboration with our clients.

Areas of Activity